about us

With a global source supply, we ship internationally and can help you or your business make medical, personal care products, cosmetics, makeup and hair care packaging of superior quality. We also offer a machining services for all in stage processes such as EDM, Mill, Lathe, Grinding, Laser, Gundrilling and programming.

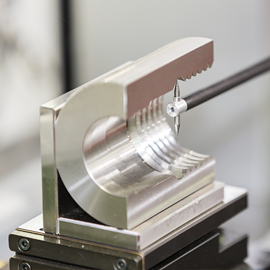

We operate under strict quality standards, the company specializes in manufacturing production and semi-production tools such as those classified by the Society of the Plastics Industry (SPI) as 101 & 102 Tools. The 101 classification signifies the finest built high production tooling and 102 is medium to high production tooling. Our expansive experience affords us the ability to successfully design and construct two and three-plate, hot manifold, stack, collapsible core, unscrewing, and multi action tight tolerance molds.

Artmark also offers manufacturing of cores, cavities, components, and manufacturing services such as product design, mold engineering, edm, wire edm, and high speed and hard milling. "Providing solutions based on the latest machining and design technology puts us on the forefront of providing the most economical choice with an unsurpassed competitive edge." “We believe in satisfying our customers through unsurpassed service and quality. We take a proactive approach to our customers needs and work with them to develop successful solutions. Our Mission Statement says it all…

The mission of Artmark Mold & Tool is to achieve the highest level of customer satisfaction obtainable by providing superior customer service, unsurpassed quality products, and on time deliveries of multi-cavitational, class 101 and 102 production molds. Artmark Mold &Tool will do “whatever it takes to provide the vital link between the inception of our customer's design and the quality of our finished product”

Mark Ura

Vice President

A Few Facts

22

Machining Services

518

Clients worked with

3680

Molds Built

12

Awards we won

our services

Fast Turn Around Time

As with any consumer driven industy, our customers can depend on our proactive approach to suppling custom designed molds. With a full range of in-house machining capabilites and state of the art equiptment we are proud to be the mold shop in the northeast.

Custom design of form fit

Does your part require special mold actions? Unscrewing, side action cam, four way split ... Our engineering department uses full 3D integrated mold design software to build your tool to custom specifications. Should a rapid turnaround be required your part may form fit into some mold designs which include side action inside center gated mold designs (send a 3d model and we can run a feasibility study).

Advanced Manufacturing

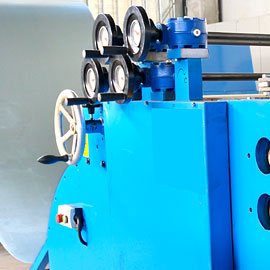

With a wide range of machining capabilities we can produce some of the most complex tooling or supplement your manufacturing needs with our 5-axis milling, molf frame VMC's, Wire EDM, Sinker EDM, gun-drill, OD/ID grinding, Laser engraving, 3d prininting ....

Adaptive Service

Molders are not our only customers, other moldmakers are too. Do you have a overload on your EDM, is your part not within your grinders capability or do you not have a 5-axis machining center. Send us the part and we'll perform only the maching service you need.

Testimonials

Had my mold parts fast and done right. They took care of everything from A to Z.

These guys are great, very professional and get the job done.

I am very pleased with the help of Mark and his team, strongly recommended!

One of the only mold shops to mave such a quick turnaround on 5-axis work.

our products

"It takes the right company to design and build a mold properly"

1. Inside gated Surlyn Cap

2. Deep inside gated PE package

3. Array of package collars and actuators

4. Spray thru multi piece assembly

5. Inside gated surlyn cap

6. Plated ABS cap with fine engraving detail

10. (ICG) Inside center gated surlyn cap

11. (ICG) Inside center gated surlyn cap

12. ABS plated spray thru cap

13. ABS plated spray thru caps

14. ABS 4-way cap with five piece cavity

15. Array of closures, tooling by Artmark

1. Inside gated Surlyn Cap

2. Deep inside gated PE package

3. Array of package collars and actuators

contact us

Find us

Artmark Mold & Tool Corp.742 Paterson Avenue

East Rutherford, NJ 07073

- Phone:

FAX: - 201 935 3377

201 933 2240

E-mail: info@artmarkmold.com