Mold Design Services

"It takes the right company to design and build a mold properly"

Anyone can build a mold, but it takes the right company to design and build a mold properly. Artmark Mold & Tool Co., Inc. is an engineering driven company and we take the upfront time and effort required to design a mold that functions properly…the first time. We work with our customers to ensure proper wall thickness, rib thickness, draft, finish, gating, venting, etc. to ensure your part is to specification and exceeds your requirements.

Anyone can build a mold, but it takes the right company to design and build a mold properly. Artmark Mold & Tool Co., Inc. is an engineering driven company and we take the upfront time and effort required to design a mold that functions properly…the first time. We work with our customers to ensure proper wall thickness, rib thickness, draft, finish, gating, venting, etc. to ensure your part is to specification and exceeds your requirements.

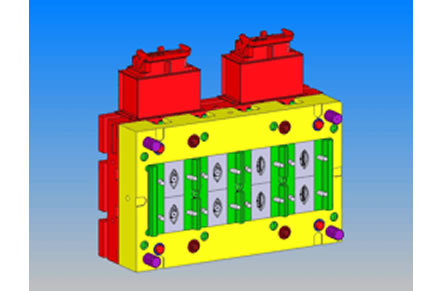

Our solid modeling CAD packages allows us to generate designs quicker and more thorough than 2d packages. Moreover, solids allows us to operate the mold before it is even built to ensure it works properly including opening, closing, actions, ejection, and injection. We use Moldex3D™ to ensure proper cavity fill. Solid designs also enable us to go directly from engineering to programming and machining…yet another reduction in delivery times.

Signature Mold, Mold Design ServicesBlueprints are the generated detailing every component from the assembly, moldbase, cores, cavities, inserts, right down to the mold strap. All our designs are consistently updated to reflect any changes ever made to your mold. This ensures that your design matches the mold. Why is this critical? First, you can track the progression of any changes in our revision block.

Second, should a detail need to be remade you will not need to reverse engineer the existing piece. You can work directly to the prints. Lastly, it allows for easier preventative maintenance.

At the completion of a project Artmark Mold & Tool Co., Inc. provides our customers with a binder that contains everything critical to the mold including product prints, product file acceptance forms, mold design acceptance forms, bill of materials, complete mold drawings, maintenance guidelines, any other pertinent information such as hot manifold paperwork, and a cd-rom containing all previous as well as the mold design in native Solidoworks and .igs formats.